Premium Quality Body Bolts for Enhanced Performance and Durability in Auto Applications

Nov . 25, 2024 10:53 Back to list

Premium Quality Body Bolts for Enhanced Performance and Durability in Auto Applications

The Importance of High-Quality Body Bolts in Automotive Engineering

In the world of automotive engineering, the integrity and safety of a vehicle hinge significantly on its components, and body bolts are among the most essential fasteners used. These seemingly small elements play a critical role in holding together various parts of a vehicle’s structure, influencing both performance and safety. When it comes to body bolts, opting for high-quality materials and manufacturing processes can make all the difference.

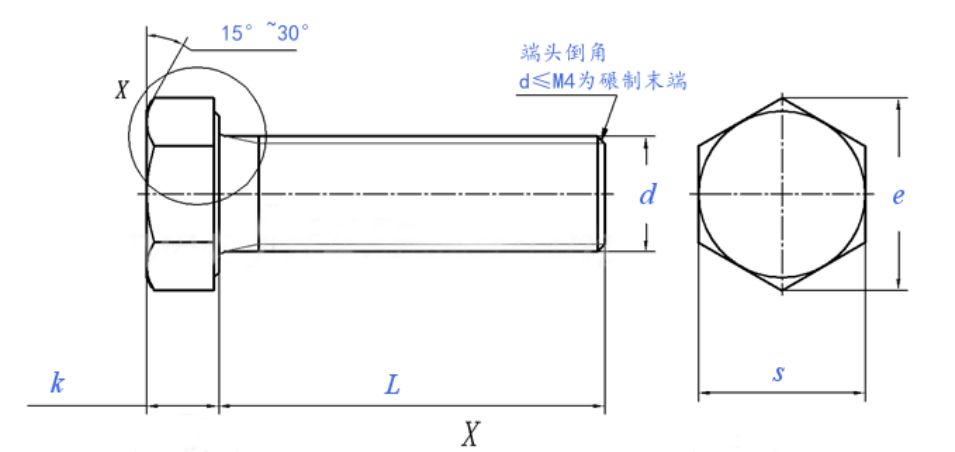

Understanding Body Bolts

Body bolts are fasteners specifically designed to secure the vehicle body to the chassis, along with other attached components like doors, fenders, and hoods. These bolts must withstand extensive forces and vibrations during driving, as well as harsh environmental conditions such as moisture, heat, and road debris. Standard bolts may not provide the necessary strength or resilience required in such demanding applications, making the selection of high-quality body bolts crucial.

Benefits of High-Quality Body Bolts

1. Durability High-quality body bolts are constructed from advanced materials such as high-tensile steel or stainless steel, which provide excellent resistance to wear and deformation. This durability is essential to ensure that the bolts do not fail under stress, which could compromise the structural integrity of the vehicle and endanger occupants.

2. Corrosion Resistance Quality body bolts often undergo treatments and coatings that enhance their resistance to rust and corrosion. In automotive applications, exposure to moisture, salt, and other corrosive substances is common. Premium body bolts resist these elements, thereby prolonging their lifespan and maintaining the vehicle’s structural integrity.

high quality body bolts

3. Precision Fit High-quality body bolts are manufactured to precise specifications, ensuring a proper fit within the designated holes. This precision minimizes the risk of loosening over time, which can lead to rattling, misalignment, or even catastrophic failures. A secure fit also allows for better load distribution across the vehicle’s body, contributing to overall stability and safety.

4. Enhanced Safety The safety of a vehicle is paramount. High-quality body bolts provide the peace of mind that comes from knowing that all components are securely fastened. In the event of a collision, well-fitted body bolts contribute to better energy absorption, potentially lessening the impact on passengers.

5. Cost-Effectiveness Although high-quality body bolts may entail a higher initial cost than their lower-quality counterparts, they often lead to long-term savings. Their durability means less frequent replacements and reduced maintenance costs over the lifespan of the vehicle, making them a prudent investment for manufacturers and vehicle owners alike.

Choosing the Right Body Bolts

With the importance of body bolts established, how can manufacturers and mechanics ensure they choose the right ones? First, they should consider the specific requirements of the vehicle, such as weight, expected load, and environmental factors. Investing in reputable suppliers who provide detailed specifications and certifications for their products is also crucial. Additionally, understanding the various grades of bolts available, such as grade 8 or 10.9, can aid in making the right selection based on the application.

Conclusion

In conclusion, high-quality body bolts are an indispensable part of automotive design and safety. Their superior durability, corrosion resistance, and precision fit directly impact the structural integrity and performance of a vehicle. By prioritizing the use of high-quality body bolts, manufacturers can enhance vehicle safety, reduce long-term costs, and deliver reliable products to consumers. As automotive technology continues to evolve, the importance of quality in seemingly minor components like body bolts should never be underestimated.

Latest news

-

Premium Cabinet Bolts Supplier | Wholesale & Custom Solutions

NewsAug.24,2025

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025