cap head socket bolts

1月 . 10, 2025 12:38 Back to list

cap head socket bolts

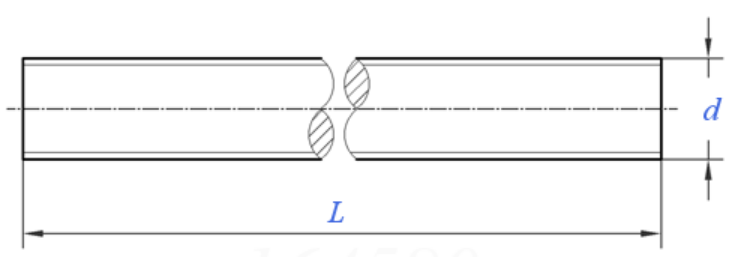

In the fast-paced world of manufacturing and construction, every tiny component plays a crucial role in the success of a project. Cap head socket bolts are one of those essential elements that often go unnoticed but contribute significantly to the strength and durability of structures. From heavy machinery assembly to automotive applications, these bolts are indispensable due to their unique features and capabilities.

Trustworthiness when dealing with cap head socket bolts also involves working with reputable suppliers who adhere to stringent quality standards. A reliable manufacturer will ensure that the bolts meet international standards such as ISO 9001 or ASTM, guaranteeing consistency in dimensions, material quality, and performance. Moreover, obtaining bolts that are traceable to a specific batch provides an extra layer of confidence in their use, especially for critical applications where failure is not an option. Emphasizing from real-world experience, the installation of cap head socket bolts should always follow the manufacturer's recommended torque specifications. Over-tightening can lead to head stripping or thread damage, compromising the bolt's performance. Conversely, under-tightening may result in inadequate clamping force, risking joint failure. Regular maintenance checks, including inspection and re-torqueing as necessary, can extend the lifespan of these bolts and ensure continued reliability in their applications. In conclusion, cap head socket bolts are a backbone of mechanical and structural applications, appreciated for their design, strength, and versatility. Understanding their specifications, materials, and appropriate usage scenarios can enhance decision-making and result in more successful project outcomes. For industries and professionals that rely on these components, remaining informed about the latest developments and standards is crucial, ensuring that each bolt utilized serves its purpose effectively and safely.

Trustworthiness when dealing with cap head socket bolts also involves working with reputable suppliers who adhere to stringent quality standards. A reliable manufacturer will ensure that the bolts meet international standards such as ISO 9001 or ASTM, guaranteeing consistency in dimensions, material quality, and performance. Moreover, obtaining bolts that are traceable to a specific batch provides an extra layer of confidence in their use, especially for critical applications where failure is not an option. Emphasizing from real-world experience, the installation of cap head socket bolts should always follow the manufacturer's recommended torque specifications. Over-tightening can lead to head stripping or thread damage, compromising the bolt's performance. Conversely, under-tightening may result in inadequate clamping force, risking joint failure. Regular maintenance checks, including inspection and re-torqueing as necessary, can extend the lifespan of these bolts and ensure continued reliability in their applications. In conclusion, cap head socket bolts are a backbone of mechanical and structural applications, appreciated for their design, strength, and versatility. Understanding their specifications, materials, and appropriate usage scenarios can enhance decision-making and result in more successful project outcomes. For industries and professionals that rely on these components, remaining informed about the latest developments and standards is crucial, ensuring that each bolt utilized serves its purpose effectively and safely.

Next:

Latest news

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025