custom made screws

Նյմ . 21, 2024 03:41 Back to list

custom made screws

Custom Made Screws Precision and Versatility in Manufacturing

In the realm of manufacturing, the small details often make a significant impact on the overall quality and performance of a product. Custom made screws are one such detail that can enhance the efficiency and effectiveness of mechanical assemblies across various industries. These specialized fasteners are tailored to meet specific requirements, ensuring optimal fit, strength, and functionality.

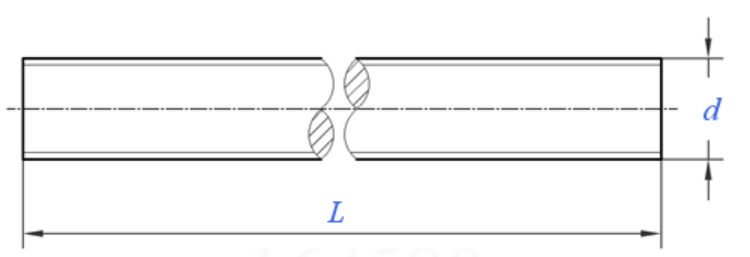

One of the primary advantages of custom made screws is their versatility. Unlike standard screws, which come in predetermined sizes and designs, custom screws can be manufactured to accommodate unique specifications. This includes variations in length, diameter, thread type, and material composition. Whether it’s for aerospace applications requiring lightweight titanium screws or automotive uses demanding high-strength steel, custom options allow manufacturers to select materials that best suit their needs.

The customization process itself involves collaboration between engineers and suppliers. Engineers provide detailed specifications and designs, which can often include intricate features not commonly found in standard screws. Advanced technologies, such as CNC machining and 3D printing, facilitate the production of these screws with high precision. This level of customization not only improves the performance of the final product but also reduces the risk of failure or malfunction due to ill-fitting components.

custom made screws

Moreover, custom made screws can contribute to cost savings in the long run

. By designing screws that perfectly match the application, companies can minimize waste and avoid the additional expenses of modifying or replacing ill-fitting parts. Additionally, custom screws can expedite assembly processes, as they often integrate more seamlessly into the designs, leading to faster production times.The demand for custom made screws is on the rise as businesses increasingly seek tailored solutions to meet their operational challenges. Industries such as electronics, construction, and robotics are constantly evolving, requiring fasteners that can keep up with the pace of innovation. As a result, suppliers are enhancing their capabilities to meet these demands, offering a wider array of materials and manufacturing techniques.

In conclusion, custom made screws represent a critical component in modern manufacturing, providing precision, versatility, and cost-effectiveness. As industries continue to innovate and evolve, the importance of these specialized fasteners will only increase, making them an essential consideration for engineers and manufacturers alike. Embracing the potential of custom made screws can lead to improved product performance and a competitive edge in the marketplace.

Latest news

-

Wire Bolts Suppliers: Durable & Reliable Fasteners for Every Project

NewsAug.25,2025

-

Premium Cabinet Bolts Supplier | Wholesale & Custom Solutions

NewsAug.24,2025

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025