break away bolts suppliers

Nov . 07, 2024 00:25 Back to list

break away bolts suppliers

Breakaway Bolts An Overview of Suppliers and Their Importance in Various Industries

In the world of engineering and manufacturing, the functionality and reliability of components are paramount. One such component that plays a critical role in safety and operational efficiency is the breakaway bolt. Breakaway bolts, also known as shear bolts, are specialized fasteners designed to fail at a predetermined torque level. This feature allows them to protect machinery, equipment, and structures from damage by breaking under excessive stress.

Understanding Breakaway Bolts

The primary purpose of breakaway bolts is to serve as a failsafe mechanism. When too much force is applied to a component, the bolt will shear off instead of allowing the entire assembly to fail catastrophically. This can be especially crucial in industries such as construction, oil and gas, automotive, and aerospace, where equipment overloads can lead to dangerous situations.

Breakaway bolts come in various sizes, materials, and designs, depending on their intended application. Common materials include steel, stainless steel, and specialty alloys, which are chosen based on their mechanical properties and compatibility with the environment. The design can vary from simple threaded bolts to more complex configurations that enhance their performance.

Importance of Reliable Suppliers

The effectiveness of breakaway bolts hinges not only on their design and material but also significantly on the suppliers from whom they are sourced. Reliable suppliers ensure that the bolts meet industry standards, safety regulations, and performance specifications. Quality control is essential, as even minor defects can compromise the integrity of the fastening system.

break away bolts suppliers

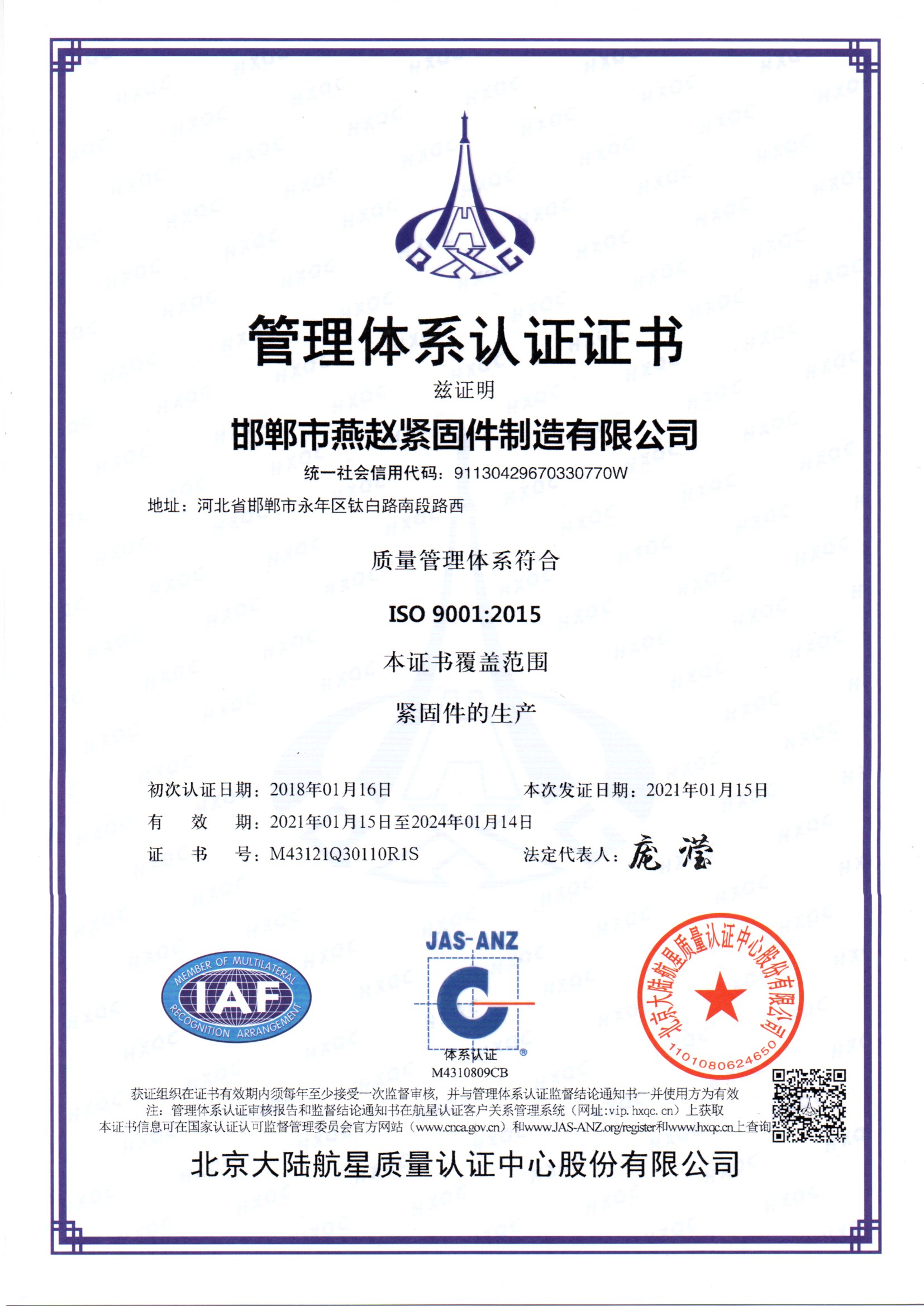

When selecting suppliers for breakaway bolts, it is crucial to consider their reputation, experience in the industry, and certifications. A supplier with a proven track record in providing high-quality fasteners will likely adhere to strict manufacturing processes and quality assurance protocols. This minimizes the risk of purchasing subpar products that could lead to failures and costly downtimes.

Key Suppliers in the Market

Several suppliers have established themselves as leaders in the market for breakaway bolts. Companies like Fastenal, McMaster-Carr, and Grainger offer a wide range of fasteners, including breakaway bolts, and provide additional resources such as expert advice and technical support. These suppliers not only supply standard products but also offer custom solutions tailored to specific customer needs.

Another noteworthy supplier is Bolt & Nut Manufacturing, which specializes in high-performance fasteners for critical applications. Their emphasis on research and development ensures that they are at the forefront of innovation, providing advanced materials and designs that enhance the functionality of breakaway bolts.

Furthermore, global suppliers such as Hilti and Thyssenkrupp have also made their mark in supplying high-quality breakaway bolts, particularly for large-scale industrial applications. Their extensive distribution networks and manufacturing capabilities make them key players in the industry.

Conclusion

In conclusion, breakaway bolts are vital components that enhance safety and reliability in various industrial applications. Choosing the right supplier is crucial to ensure that these fasteners perform as intended. By collaborating with reputable suppliers, businesses can mitigate risks associated with equipment failure and ensure operational efficiency. Quality breakaway bolts are essential for maintaining safety standards and protecting valuable assets across industries.

Latest news

-

Trusted Wire Bolts Suppliers - Durable & Reliable Solutions

NewsAug.04,2025

-

Wire Bolts Company | Premium Industrial Fasteners

NewsAug.03,2025

-

Top Wire Bolts Suppliers | AI-Optimized Fast Delivery

NewsAug.02,2025

-

Top Metric Wood Screw Companies | Durable & Reliable

NewsAug.01,2025

-

Premium Lawn Mower Handle Bolts Supplier | Fast Delivery

NewsJul.31,2025

-

Premium Silver Screws Supplier | High-Conductivity Fasteners

NewsJul.31,2025