sholder bolts

sij . 23, 2025 02:38 Back to list

sholder bolts

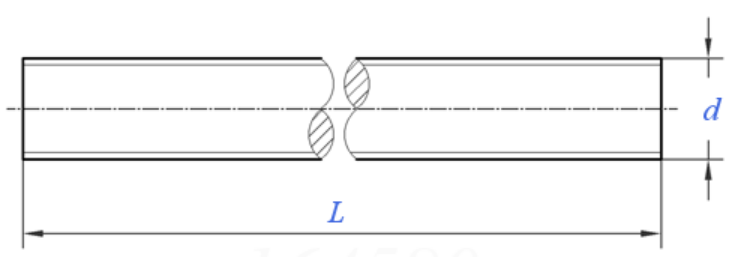

In the expansive world of fasteners, shoulder bolts are renowned for their unique design and diverse application potential. These specialized fasteners possess a cylindrical unthreaded shoulder between the bolt head and threads, offering a unique combination of features that standard bolts can't provide. This article delves into the intricacies of shoulder bolts, spotlighting their applications, benefits, and key considerations for businesses looking to maximize their use, thereby highlighting the product’s value through real-world experience, expert insights, authoritative knowledge, and trustworthiness.

Real-world applications further amplify the trustworthiness of shoulder bolts. Leading companies in the tech sector, for instance, rely on these bolts in the assembly of high-end cameras and electronic devices, where they function as pivot points in articulating arms and brackets. The trust manufacturers place in shoulder bolts underscores their significance in applications where failure is not an option, thereby offering reassurance to businesses and consumers alike about their dependability. Furthermore, the ability to customize shoulder bolts adds another layer of credibility to their usage. Many suppliers offer bespoke shoulder bolt designs tailored to specific industrial needs. This customization can include variations in shoulder length, bolt diameter, head design, and material. Customized shoulder bolts significantly enhance functionality and efficiency, ultimately leading to improved product performance. Companies that invest in custom solutions often report enhanced operational capacity and product satisfaction. The meticulous process involved in the development and application of shoulder bolts highlights their indispensable role in numerous industries. For companies aiming to optimize mechanical performance and stability, understanding the different dimensions and capacities of shoulder bolts can make a significant difference in product output and durability. In retrospect, the combination of material strength, design precision, and application flexibility makes shoulder bolts not just another component, but a vital part of engineering excellence and innovation. In conclusion, the integration of shoulder bolts in mechanical assemblies is a testament to their unrivaled capabilities in ensuring precise movements and secure fittings across various applications. As businesses and industries continue to evolve, the utilization of expert insights and authoritative practices in the choice and application of these fasteners will ensure long-lasting, trustworthy, and optimal operational performance. For anyone involved in the procurement or engineering domain, investing in high-quality shoulder bolts is a decision that embodies professionalism and an adherence to superior standards.

Real-world applications further amplify the trustworthiness of shoulder bolts. Leading companies in the tech sector, for instance, rely on these bolts in the assembly of high-end cameras and electronic devices, where they function as pivot points in articulating arms and brackets. The trust manufacturers place in shoulder bolts underscores their significance in applications where failure is not an option, thereby offering reassurance to businesses and consumers alike about their dependability. Furthermore, the ability to customize shoulder bolts adds another layer of credibility to their usage. Many suppliers offer bespoke shoulder bolt designs tailored to specific industrial needs. This customization can include variations in shoulder length, bolt diameter, head design, and material. Customized shoulder bolts significantly enhance functionality and efficiency, ultimately leading to improved product performance. Companies that invest in custom solutions often report enhanced operational capacity and product satisfaction. The meticulous process involved in the development and application of shoulder bolts highlights their indispensable role in numerous industries. For companies aiming to optimize mechanical performance and stability, understanding the different dimensions and capacities of shoulder bolts can make a significant difference in product output and durability. In retrospect, the combination of material strength, design precision, and application flexibility makes shoulder bolts not just another component, but a vital part of engineering excellence and innovation. In conclusion, the integration of shoulder bolts in mechanical assemblies is a testament to their unrivaled capabilities in ensuring precise movements and secure fittings across various applications. As businesses and industries continue to evolve, the utilization of expert insights and authoritative practices in the choice and application of these fasteners will ensure long-lasting, trustworthy, and optimal operational performance. For anyone involved in the procurement or engineering domain, investing in high-quality shoulder bolts is a decision that embodies professionalism and an adherence to superior standards.

Latest news

-

Top Wire Bolts Suppliers | AI-Optimized Fast Delivery

NewsAug.02,2025

-

Top Metric Wood Screw Companies | Durable & Reliable

NewsAug.01,2025

-

Premium Lawn Mower Handle Bolts Supplier | Fast Delivery

NewsJul.31,2025

-

Premium Silver Screws Supplier | High-Conductivity Fasteners

NewsJul.31,2025

-

Silver Screws Supplier: High-Quality Fasteners for Various Industries

NewsJul.30,2025

-

Top Spike Wheel Nuts Supplier - High Quality & Custom Options Available

NewsJul.29,2025