Khoom Taw Qhia

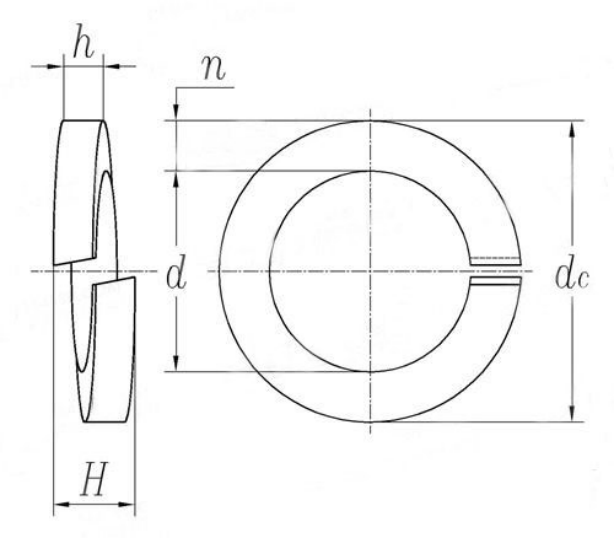

Lub nplhaib sib cais ntawm ib qho taw tes thiab khoov rau hauv ib qho helical zoo li. Qhov no ua rau lub tshuab ntxhua khaub ncaws siv lub caij nplooj ntoos hlav quab yuam ntawm lub taub hau thiab lub substrate, uas tuav lub tshuab ntxhua khaub ncaws nyuaj tiv thaiv lub substrate thiab bolt xov nyuaj rau cov txiv ntoo los yog cov xov substrate, tsim kom muaj kev sib txhuam ntau dua thiab tiv thaiv kev sib hloov. Cov qauv siv tau yog ASME B18.21.1, Los ntawm 127 B, thiab Teb Chaws Mis Kas Military Standard NASM 35338 (yav tas los MS 35338 thiab AN-935).

Lub caij nplooj ntoos hlav ntxhua khaub ncaws yog sab laug tes helix thiab tso cai rau cov xov kom nruj rau sab tes xis kev taw qhia nkaus xwb, piv txwv li kev coj ua clockwise. Thaum sab laug tes tig yog siv, lub tsa ntug tom rau hauv qab ntawm lub ntsia liaj qhov rooj los yog txiv ntseej thiab ib feem uas nws yog bolted rau, yog li resisting tig. Yog li ntawd, lub caij nplooj ntoos hlav ntxhua khaub ncaws tsis zoo ntawm sab tes xov thiab cov tawv tawv. Tsis tas li ntawd, lawv yuav tsum tsis txhob siv ua ke nrog lub tshuab ntxhua khaub ncaws hauv qab lub caij nplooj ntoos hlav ntxhua khaub ncaws, vim qhov no cais lub caij nplooj ntoos hlav ntxhua khaub ncaws los ntawm kev sib tsoo rau hauv cov khoom uas yuav tiv thaiv tig.

Cov txiaj ntsig ntawm lub caij nplooj ntoos hlav xauv lub tshuab ntxhua khaub ncaws yog nyob rau hauv cov duab trapezoidal ntawm lub tshuab ntxhua khaub ncaws. Thaum compressed rau loads ze ntawm lub zog pov thawj ntawm lub bolt, nws yuav twist thiab flatten. Qhov no txo qis lub caij nplooj ntoos hlav tus nqi ntawm bolted sib koom ua ke uas tso cai rau nws kom muaj zog ntau dua nyob rau hauv tib theem kev co. Qhov no tiv thaiv loosening.

Daim ntawv thov

The spring washer prevents nuts and bolts from turning, slipping and coming loose because of vibration and torque. Different spring washers perform this function in slightly different ways, but the basic concept is to hold the nut and bolt in place. Some spring washers achieve this function by biting into the base material (bolt) and the nut with their ends.

Spring washers are commonly used in applications involving vibration and possible slippage of fasteners. Industries that commonly use spring washers are transportation related (automotive, aircraft, marine). Spring washers may also be used in household appliances such as air handlers and clothes washers (washing machines).

|

nominal txoj kab uas hla |

2 |

2.5 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

(14) |

|

|

d |

yam tsawg kawg nkaus |

2.1 |

2.6 |

3.1 |

4.1 |

5.1 |

6.2 |

8.2 |

10.2 |

12.3 |

14.3 |

|

crest nqi |

2.3 |

2.8 |

3.3 |

4.4 |

5.4 |

6.7 |

8.7 |

10.7 |

12.8 |

14.9 |

|

|

h |

npe |

0.6 |

0.8 |

1 |

1.2 |

1.6 |

2 |

2.5 |

3 |

3.5 |

4 |

|

yam tsawg kawg nkaus |

0.52 |

0.7 |

0.9 |

1.1 |

1.5 |

1.9 |

2.35 |

2.85 |

3.3 |

3.8 |

|

|

crest nqi |

0.68 |

0.9 |

1.1 |

1.3 |

1.7 |

2.1 |

2.65 |

3.15 |

3.7 |

4.2 |

|

|

n |

yam tsawg kawg nkaus |

0.52 |

0.7 |

0.9 |

1.1 |

1.5 |

1.9 |

2.35 |

2.85 |

3.3 |

3.8 |

|

crest nqi |

0.68 |

0.9 |

1.1 |

1.3 |

1.7 |

2.1 |

2.65 |

3.15 |

3.7 |

4.2 |

|

|

H |

yam tsawg kawg nkaus |

1.2 |

1.6 |

2 |

2.4 |

3.2 |

4 |

5 |

6 |

7 |

8 |

|

crest nqi |

1.5 |

2.1 |

2.6 |

3 |

4 |

5 |

6.5 |

8 |

9 |

10.5 |

|

|

Ntau txhiab daim hnyav (steel) kg |

0.023 |

0.053 |

0.097 |

0.182 |

0.406 |

0.745 |

1.53 |

2.82 |

4.63 |

6.85 |

|

|

nominal txoj kab uas hla |

16 |

(18) |

20 |

(22) |

24 |

(27) |

30 |

36 |

42 |

48 |

|

|

d |

yam tsawg kawg nkaus |

16.3 |

18.3 |

20.5 |

22.5 |

24.5 |

27.5 |

30.5 |

36.6 |

42.6 |

49 |

|

crest nqi |

16.9 |

19.1 |

21.3 |

23.3 |

25.5 |

28.5 |

31.5 |

37.8 |

43.8 |

50.2 |

|

|

h |

npe |

4 |

4.5 |

5 |

5 |

6 |

6 |

6.5 |

7 |

8 |

9 |

|

yam tsawg kawg nkaus |

3.8 |

4.3 |

4.8 |

4.8 |

5.8 |

5.8 |

6.2 |

6.7 |

7.7 |

8.7 |

|

|

crest nqi |

4.2 |

4.7 |

5.2 |

5.2 |

6.2 |

6.2 |

6.8 |

7.3 |

8.3 |

9.3 |

|

|

n |

yam tsawg kawg nkaus |

3.8 |

4.3 |

4.8 |

4.8 |

5.8 |

5.8 |

6.2 |

6.7 |

7.7 |

8.7 |

|

crest nqi |

4.2 |

4.7 |

5.2 |

5.2 |

6.2 |

6.2 |

6.8 |

7.3 |

8.3 |

9.3 |

|

|

H |

yam tsawg kawg nkaus |

8 |

9 |

10 |

10 |

12 |

12 |

13 |

14 |

16 |

18 |

|

crest nqi |

10.5 |

11.5 |

13 |

13 |

15 |

15 |

17 |

18 |

21 |

23 |

|

|

Ntau txhiab daim hnyav (steel) kg |

7.75 |

11 |

15.2 |

16.5 |

26.2 |

28.2 |

37.6 |

51.8 |

78.7 |

114 |

|