buy stainless steel bolts in aluminum

Oct . 30, 2024 17:37 Back to list

buy stainless steel bolts in aluminum

Buying Stainless Steel Bolts for Aluminum Applications

When it comes to fastening aluminum components, choosing the right type of bolt is crucial for ensuring durability, performance, and resistance to corrosion. Among the various options available, stainless steel bolts stand out as a preferred choice for many applications involving aluminum. This article explores the benefits of using stainless steel bolts with aluminum and provides some essential tips on purchasing them.

Why Choose Stainless Steel Bolts?

Stainless steel bolts offer exceptional strength and corrosion resistance, making them ideal for various environments, including marine and high-humidity areas. Aluminum, while lightweight and versatile, can suffer from galvanic corrosion when in contact with certain metals. This phenomenon occurs when dissimilar metals are electrically coupled in the presence of an electrolyte (like water), leading to the degradation of one of the metals. Stainless steel bolts, specifically those made from grades like 304 or 316, provide a protective solution that minimizes the risk of corrosion, ensuring the longevity of your aluminum components.

Key Considerations When Buying

1. Grade of Stainless Steel The most commonly used grades are 304 and 316 stainless steel. Grade 304 is suitable for most applications, providing good corrosion resistance. However, if you are operating in more corrosive environments (like marine settings), grade 316, which contains molybdenum, offers superior resistance.

buy stainless steel bolts in aluminum

2. Size and Thread Type Ensure you purchase bolts that are the appropriate size and thread type for your specific application. Bolts come in various diameters, lengths, and thread configurations (such as coarse or fine) that must match the requirements of the materials you are working with.

3. Coatings and Finishes Some stainless steel bolts are available with additional coatings or finishes to enhance their appearance or further increase their resistance to corrosion. Be sure to check whether a specific finish is advantageous for your application, especially if aesthetics are a concern.

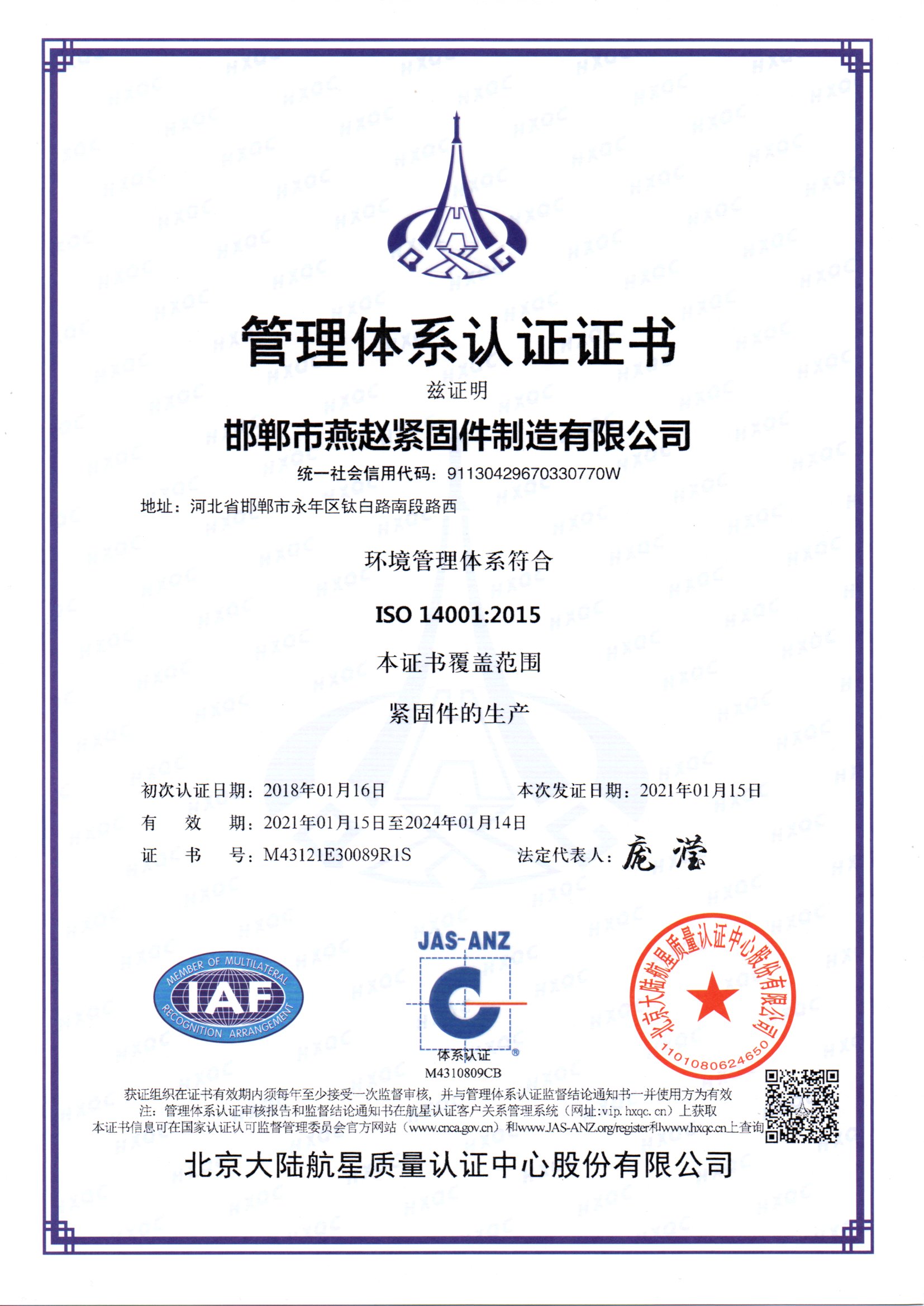

4. Certifications and Standards Always look for bolts that meet industry standards, such as ASTM or ISO certifications. This ensures that the bolts you purchase have been tested for quality and performance.

5. Price vs. Quality While it might be tempting to go for the cheapest option, it’s essential to balance cost with quality. Investing in high-quality stainless steel bolts can save you money in the long run by reducing maintenance and replacement costs.

Conclusion

Buying stainless steel bolts for aluminum applications is a prudent choice that enhances the structural integrity and lifespan of your projects. By investing time in understanding the different types of bolts available, their specifications, and the factors that influence their performance, you can make informed purchasing decisions that lead to successful outcomes in your aluminum-related endeavors.

Latest news

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025