axle u bolts

ינו . 23, 2025 04:56 Back to list

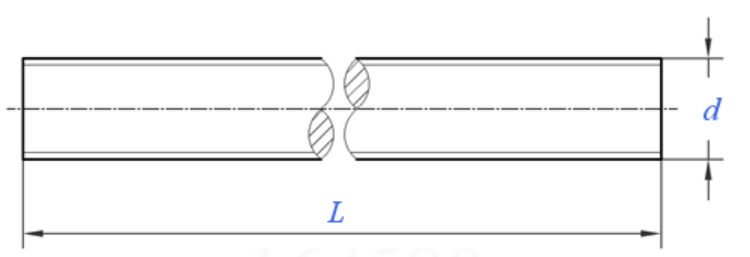

axle u bolts

Selecting the best axle U-bolts for your vehicle requires a blend of engineering insight and practical experience. These components, seemingly simple in design, play a pivotal role in the stability and safety of your vehicle's suspension system. As an expert in automotive parts, understanding the nuances of axle U-bolts is crucial for anyone involved in vehicle maintenance or modification.

A key part of advanced installation is understanding the significance of retorquing U-bolts. After initial installation, it's imperative to retorque after the first 500 miles of driving. This compensates for settling that might occur as the U-bolts and leaf springs adjust to the applied load. Regular retorquing during maintenance checks can significantly enhance the longevity of these components. When issues arise—such as irregular tire wear or a vehicle leaning to one side—scrutinizing the U-bolts should be a priority. These symptoms might indicate a loose or damaged U-bolt, necessitating immediate attention to prevent further suspension damage or compromised vehicle handling. Trustworthiness in assessing the quality of axle U-bolts lies in purchasing from proven sources. Reputable suppliers who provide certification and detailed product specifications foster confidence that the components will perform safely and effectively. Investing in high-quality U-bolts might entail a higher initial cost but is a prudent choice that safeguards against future expenses related to potential vehicle damage or accident risks. In summary, axle U-bolts, while often overlooked, are pivotal in maintaining the structural integrity of a vehicle's suspension system. A deep understanding of their material properties, measurement precision, and correct installation techniques can lead to significant improvements in vehicle safety and performance. For professionals and enthusiasts alike, staying informed about the latest advances and best practices in U-bolt technology is essential for ensuring every vehicle journey is as safe and smooth as possible.

A key part of advanced installation is understanding the significance of retorquing U-bolts. After initial installation, it's imperative to retorque after the first 500 miles of driving. This compensates for settling that might occur as the U-bolts and leaf springs adjust to the applied load. Regular retorquing during maintenance checks can significantly enhance the longevity of these components. When issues arise—such as irregular tire wear or a vehicle leaning to one side—scrutinizing the U-bolts should be a priority. These symptoms might indicate a loose or damaged U-bolt, necessitating immediate attention to prevent further suspension damage or compromised vehicle handling. Trustworthiness in assessing the quality of axle U-bolts lies in purchasing from proven sources. Reputable suppliers who provide certification and detailed product specifications foster confidence that the components will perform safely and effectively. Investing in high-quality U-bolts might entail a higher initial cost but is a prudent choice that safeguards against future expenses related to potential vehicle damage or accident risks. In summary, axle U-bolts, while often overlooked, are pivotal in maintaining the structural integrity of a vehicle's suspension system. A deep understanding of their material properties, measurement precision, and correct installation techniques can lead to significant improvements in vehicle safety and performance. For professionals and enthusiasts alike, staying informed about the latest advances and best practices in U-bolt technology is essential for ensuring every vehicle journey is as safe and smooth as possible.

Next:

Latest news

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier

NewsAug.12,2025

-

Leading Phosphated Drywall Screws Supplier | Bulk & Custom Orders

NewsAug.11,2025

-

Top Wire Bolts Company: Manufacturers, Exporters & Suppliers

NewsAug.10,2025