buy brass machine screws

Dàmh . 31, 2024 09:24 Back to list

buy brass machine screws

A Complete Guide to Buying Brass Machine Screws

When it comes to assembling or repairing machinery and equipment, choosing the right fasteners is crucial. Among the various types of fasteners available, brass machine screws are a popular choice for many applications due to their unique properties. This article will guide you through the benefits of brass machine screws and provide tips on how to buy them effectively.

What are Brass Machine Screws?

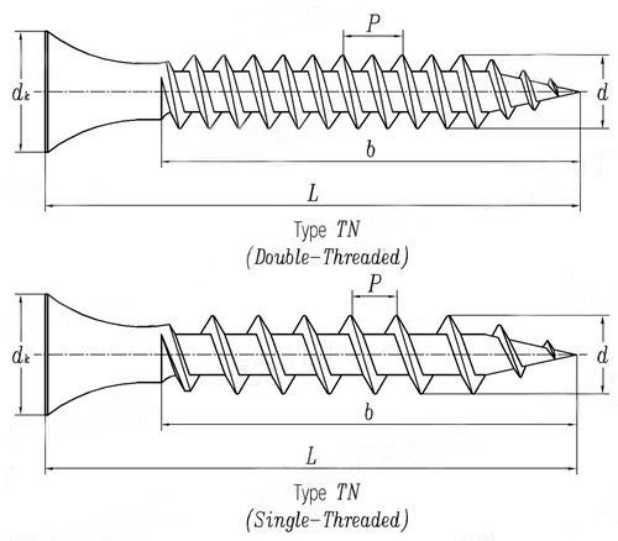

Brass machine screws are fasteners made from brass, an alloy of copper and zinc. They are designed with a uniform diameter and a pointed end for easy insertion. These screws often come with a variety of head styles, including slotted, Phillips, or hex, to suit different tools and applications.

Why Choose Brass Machine Screws?

1. Corrosion Resistance One of the significant advantages of brass is its resistance to corrosion. This makes brass machine screws ideal for applications where exposure to moisture or chemicals is a concern, such as in marine or outdoor environments.

2. Aesthetic Appeal Brass has a distinctive golden color and shiny finish that makes it an attractive option for visible components in machinery or decorative applications. If appearance matters, brass machine screws can enhance the overall look of your project.

3. Good Electrical Conductivity Brass is a good conductor of electricity, making brass machine screws suitable for electrical applications. If you are working on electrical devices or circuit boards, using brass screws can contribute to efficient performance.

4. Malleability Brass is relatively easy to work with and can be easily formed or threaded. This property makes it an excellent choice for intricate designs and custom applications.

buy brass machine screws

Tips for Buying Brass Machine Screws

1. Know Your Specifications Before purchasing brass machine screws, it is essential to know the specific requirements of your project. This includes the diameter, length, thread type, and head style of the screws. Ensuring you have the right specifications will help you avoid compatibility issues.

2. Choose the Right Grade Brass screws come in various grades, which can affect their strength and corrosion resistance. For most applications, low-lead brass screws are sufficient. However, for high-stress environments, consider choosing higher-grade brass screws designed for heavy-duty use.

3. Check for Quality Quality is paramount when it comes to fasteners. Inspect the screws for signs of defects, such as rough threads or inconsistencies in the finish. It’s advisable to buy from reputable suppliers known for their quality products.

4. Consider Bulk Purchasing If you are working on a large project or require a significant quantity of screws, consider purchasing in bulk. Many suppliers offer discounts for bulk orders, which can save you money in the long run.

5. Read Reviews and Compare Prices Before making a purchase, take the time to read reviews and compare prices from different suppliers. This will help you find the best deal while ensuring you are getting quality brass machine screws.

Conclusion

Brass machine screws are an excellent choice for various applications due to their durability, corrosion resistance, and aesthetic appeal. By understanding the specifications, quality, and price factors, you can make informed decisions when purchasing brass screws for your projects. Whether you are a hobbyist or a professional, choosing the right fasteners will lead to successful assemblies and repairs. Happy fastening!

Latest news

-

Reliable Cabinet Bolts Supplier | Quality & Bulk Fasteners

NewsAug.07,2025

-

Wire Bolts Suppliers & Manufacturer | Factory Direct Price

NewsAug.06,2025

-

Premium Wire Bolts Suppliers | High-Quality Bolts

NewsAug.05,2025

-

Trusted Wire Bolts Suppliers - Durable & Reliable Solutions

NewsAug.04,2025

-

Wire Bolts Company | Premium Industrial Fasteners

NewsAug.03,2025

-

Top Wire Bolts Suppliers | AI-Optimized Fast Delivery

NewsAug.02,2025