6 inch u bolts factories

Dùbh . 13, 2024 15:38 Back to list

6 inch u bolts factories

Understanding 6-Inch U-Bolts The Backbone of Industrial Applications

U-bolts are critical components in various industries, providing essential support and stability to structures and machinery. Among the myriad types available, the 6-inch U-bolt stands out for its versatility and capability in both residential and industrial applications. This article delves into what 6-inch U-bolts are, their manufacturing process, the importance of factories producing them, and their various applications.

What are 6-Inch U-Bolts?

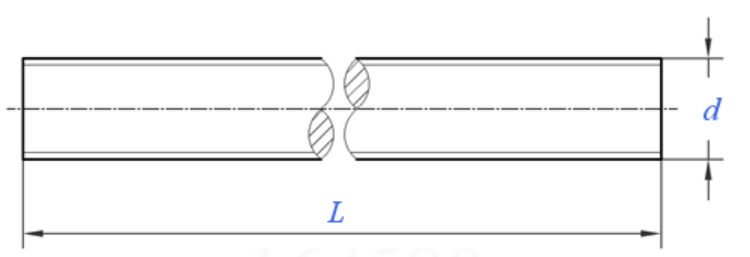

A U-bolt is a bolt shaped like the letter U, designed to hold objects together. The measurement of 6 inches typically refers to the length of the shank, which is the straight part of the bolt that goes through the material it is securing. U-bolts are usually made from high-strength materials to withstand significant tension and pressure, making them ideal for tasks requiring durability and reliability.

U-bolts come with threads at each end, allowing them to be paired with nuts to secure the objects tightly. Depending on their intended use, they can be manufactured with different diameters, materials, and finishes. Common manufacturing materials include steel, stainless steel, and sometimes plastic-coated finishes for added corrosion resistance.

The Manufacturing Process of 6-Inch U-Bolts

The production of 6-inch U-bolts involves several steps that begin with raw material selection. Factories typically choose high-quality steel or alloy that meets specific strength and durability requirements. Following this, the manufacturing process includes

1. Cutting Raw material bars are cut to the required length, usually slightly longer than 6 inches to accommodate bending and threading. 2. Bending The cut bars are then heated and bent into a U-shape using specialized machinery that ensures the curves are uniform and meet the specified dimensions.

3. Threading Once bent, each end of the U-bolt is threaded to allow for nut attachment. This is done using threading machines that create precise and standard thread patterns for compatibility with various nuts.

4. Finishing After threading, the U-bolts undergo a finishing process that may include plating or coating to improve corrosion resistance and extend the product's lifespan. Common finishes include zinc plating or black oxide.

5. Quality Control Before packaging and shipping, U-bolts are subjected to quality control checks to ensure they meet industry standards and specifications. This may involve tensile strength testing, measuring dimensions, and inspecting finishes.

6 inch u bolts factories

The Role of Factories

Factories that specialize in the production of U-bolts play a fundamental role in various sectors, including construction, automotive, and agriculture. Their expertise not only guarantees the quality and reliability of the bolts but also enables customization based on specific customer needs.

By leveraging advanced technology and skilled labor, these factories can produce large quantities of U-bolts while maintaining strict quality standards. Moreover, they contribute to the economy by providing jobs, facilitating the supply chain, and supporting other industries that rely on their products.

Applications of 6-Inch U-Bolts

The versatility of 6-inch U-bolts means they are found in many applications

1. Automotive In vehicles, U-bolts are often used to secure leaf springs and axles.

2. Construction U-bolts are critical in anchoring plumbing and electrical systems, as well as supporting structural elements.

3. Agricultural Equipment They are used to mount various components of farm machinery, ensuring that everything remains secure during operation.

4. Industrial Settings U-bolts are commonly used in HVAC systems, where they attach ducts and pipes, ensuring that the systems remain stable and functional.

Conclusion

6-inch U-bolts are more than just simple components; they are vital elements that enhance the functionality and safety of numerous structures and applications. Factories producing these essential parts ensure high-quality manufacturing standards and cater to a diverse range of needs across multiple industries. As technology advances, the processes and materials used in producing U-bolts will likely continue to evolve, ensuring they remain reliable and indispensable tools in both everyday and industrial applications.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025