grade8.8 stud bolt factories

Urr . 02, 2024 09:16 Back to list

grade8.8 stud bolt factories

Understanding Grade 8.8 Stud Bolt Factories

In the world of industrial manufacturing, the importance of fasteners cannot be overstated. Among the various types of fasteners, stud bolts play a crucial role in various applications, most notably in construction, mechanical engineering, and heavy machinery. This article focuses on Grade 8.8 stud bolt factories, examining their significance, production processes, and the industries they serve.

What are Grade 8.8 Stud Bolts?

Grade 8.8 stud bolts are high-strength fasteners made from carbon steel, specifically designed to endure heavy loads and stress. The grading system denotes the tensile strength and yield strength of the bolts; in this case, Grade 8.8 signifies a minimum tensile strength of 800 MPa and a yield strength of 640 MPa. Such specifications make these bolts suitable for critical applications where failure is not an option.

The Manufacturing Process

The production of Grade 8.8 stud bolts involves several meticulous steps, ensuring that each bolt meets stringent quality standards. The process begins with selecting high-quality raw materials, typically carbon steel. The steel is then subjected to heating and forging processes to shape it into the desired form. Precision is key here, as even a minor deviation can compromise the bolt’s performance.

Once forged, the studs undergo a process called heat treatment, where they are heated and cooled to enhance their mechanical properties. This process increases the hardness and strength of the bolts, making them capable of withstanding high levels of stress. After heat treatment, the bolts are usually finished with coatings to protect against corrosion and wear.

grade8.8 stud bolt factories

Quality Control Standards

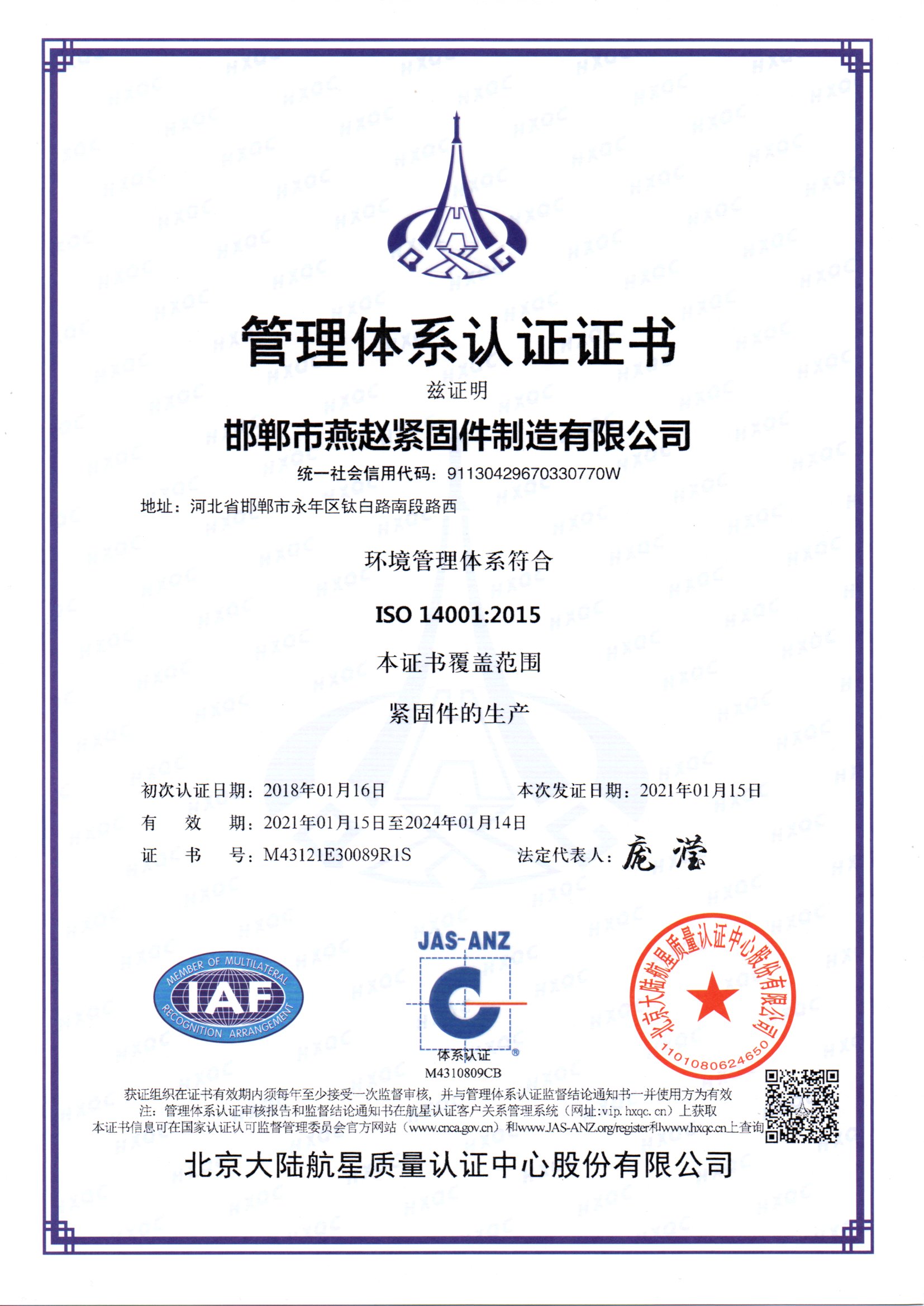

Quality assurance is paramount in the manufacturing of Grade 8.8 stud bolts. Factories implement rigorous testing protocols to ensure every batch of bolts meets international standards. This includes non-destructive testing, tensile testing, and dimensional inspections. Factories may adhere to international standards such as ISO 898-1, which outlines the requirements for high-strength bolts and screws. This commitment to quality ensures safe and reliable products for end-users.

Industries Served

Grade 8.8 stud bolts are utilized across a wide spectrum of industries. In construction, they are indispensable in steel structures, bridges, and towers, providing the necessary strength to hold components together. In the automotive and aerospace industries, these bolts are critical for assembling engines and structural components that endure significant forces. Additionally, industries like oil and gas rely on high-strength fasteners for machinery that operates in extreme conditions.

Future Trends in Manufacturing

As technology advances, Grade 8.8 stud bolt factories are increasingly adopting automated processes and robotics to enhance efficiency and precision. This modernization contributes to faster production times and reduced labor costs, allowing manufacturers to remain competitive in a global market. Furthermore, an increasing emphasis on sustainability is pushing factories to adopt eco-friendly practices, such as minimizing waste and conserving energy.

In conclusion, Grade 8.8 stud bolt factories are pivotal in ensuring the availability and reliability of high-strength fasteners used across various industries. Their commitment to quality manufacturing, adherence to standards, and adaptation to evolving technologies play a crucial role in supporting modern engineering and construction challenges. As we move forward, the significance of these factories will only continue to grow, underpinning advancements in countless industrial applications.

Latest news

-

High Strength Black & Galvanized Hex Bolts DIN933/931 GB5782/5783

NewsJul.20,2025

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025