best aluminum set screws

nov. . 11, 2024 08:01 Back to list

best aluminum set screws

The Best Aluminum Set Screws A Comprehensive Guide

When it comes to fastening solutions, set screws play a crucial role in numerous applications across various industries. Among the different materials used for manufacturing these vital components, aluminum has garnered significant attention due to its unique properties. In this article, we'll explore the best aluminum set screws available, their benefits, and what to consider when choosing the right type for your project.

Understanding Set Screws

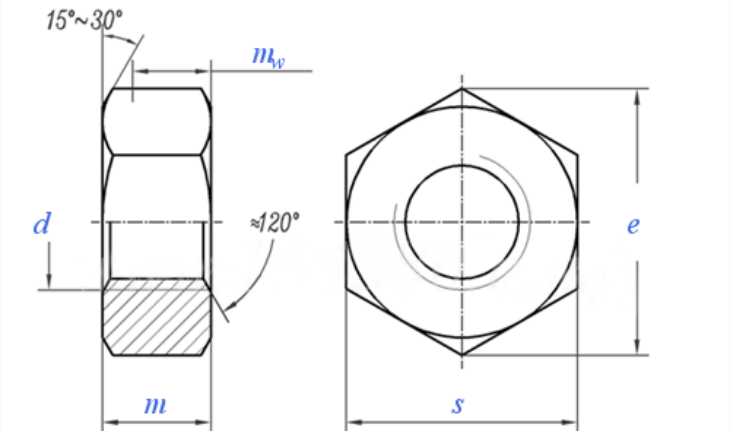

Set screws are fasteners designed to hold an object in place without the need for a nut. They are often used to secure one object within another, such as locking a gear or pulley onto a shaft. Typically installed in a threaded hole, set screws can be either fully threaded or partially threaded, allowing for versatile applications in mechanical assemblies.

The Advantages of Aluminum Set Screws

1. Lightweight One of the standout features of aluminum set screws is their low density. This significantly reduces the overall weight of assemblies, making them an excellent choice for applications in aerospace, automotive, and other industries where weight savings are paramount.

2. Corrosion Resistance Aluminum naturally forms a protective oxide layer, which makes it resistant to corrosion. This property is particularly beneficial in environments that expose fasteners to moisture or corrosive chemicals, ensuring longevity and durability.

3. Ease of Machinability Aluminum is relatively easy to machine, allowing manufacturers to produce precisely sized set screws with fine tolerances. This precise manufacturing capability ensures a better fit and reliable performance in applications.

4. Conductivity Aluminum is an excellent conductor of heat and electricity, making aluminum set screws ideal for electrical applications where thermal and electrical conductivity is necessary.

Popular Types of Aluminum Set Screws

When selecting aluminum set screws, it’s essential to understand the various types available

best aluminum set screws

- Cup Point Set Screws These screws have a concave end that digs into the surface of the material being secured. They provide a strong grip and are ideal for applications requiring a substantial hold.

- Flat Point Set Screws Featuring a flat end, these screws are suitable for securing items without causing deformation. They are best used when surface damage is a concern.

- Dog Point Set Screws These screws have a cylindrical tip that allows for precise alignment without digging into the workpiece. They are perfect for applications where adjustment is required.

- Cone Point Set Screws The pointed tip allows for easy engagement and is efficient at providing strong grip strength. These types are ideal where secure fastening is critical.

Factors to Consider When Choosing Aluminum Set Screws

1. Load Requirements Evaluate the amount of load the set screw will need to bear. Ensure that the screw’s tensile strength meets your application’s demands.

2. Corrosive Environment Consider the environment in which the set screw will be used. If it’s likely to be exposed to moisture or chemicals, aluminum's corrosion resistance may be a deciding factor.

3. Size and Threading It's crucial to choose the correct size and thread type for compatibility with existing components. This ensures a secure fit and reliable performance.

4. Installation Method Depending on whether you'll be utilizing a tool or fastening by hand, select the appropriate socket or drive style that matches your equipment.

Conclusion

Aluminum set screws are an excellent choice for many applications due to their lightweight nature, corrosion resistance, and machinability. By understanding the benefits of this type of fastener and considering the various types and factors involved, you can make an informed decision that enhances the reliability and efficiency of your projects. Whether in aerospace, automotive, or general manufacturing, selecting the right aluminum set screw can significantly impact the overall success of your assembly.

Latest news

-

High-Quality Cabinet Bolts – Reliable Factory, Trusted Company & Leading Suppliers

NewsJun.10,2025

-

Dragon Bolts UNF Wholesale – Top OSRS Dragon Bolts UNF Manufacturer & Exporter

NewsJun.10,2025

-

Premium Wind Lock Washers - Secure Anti-Vibration Solution

NewsJun.10,2025

-

Stainless Steel Socket Head Cap Screws High Strength & Corrosion-Resistant

NewsJun.10,2025

-

Shake Proof Washers Durable Anti-Vibration Locking Solutions

NewsJun.09,2025

-

Premium Window Screws Manufacturer & Exporter Durable Solutions

NewsJun.09,2025