High-Strength Stud Bolt Steel Deck Durable & Custom Solutions

May . 20, 2025 11:43 Back to list

High-Strength Stud Bolt Steel Deck Durable & Custom Solutions

- Introduction to Industrial Fastening Solutions

- Technical Superiority in Manufacturing

- Market Data & Industry Demand Analysis

- Supplier Comparison Matrix

- Custom Engineering Specifications

- Project Implementation Case Studies

- Future Trends in Structural Connectors

(stud bolt steel deck)

Essential Components for Modern Infrastructure

High-grade stud bolt steel deck

systems form the backbone of industrial construction, with global demand projected to reach $4.2 billion by 2028 (GMI 2023). These specialized fasteners enable secure load distribution in critical applications ranging from power plants to offshore platforms.

Technical Superiority in Manufacturing

Leading stud bolt steel deck factories employ cold forging techniques that enhance tensile strength by 30-40% compared to traditional methods. Our production process features:

- ISO 898-1:2013 certified grade 8.8/10.9 alloys

- Zinc-nickel coating achieving 1,200+ hours salt spray resistance

- Automated torque calibration within ±2% tolerance

Market Data & Industry Demand

The structural steel sector requires 18-22 million metric tons of fasteners annually, with stud bolt decks capturing 34% market share. Regional consumption patterns reveal:

| Region | Annual Growth | Key Applications |

|---|---|---|

| Asia-Pacific | 6.8% | Energy Infrastructure |

| North America | 4.1% | Commercial High-Rises |

| Europe | 3.7% | Transportation Networks |

Supplier Comparison Matrix

| Manufacturer | Lead Time | MOQ | Certifications |

|---|---|---|---|

| GlobalFasten Tech | 14 days | 5,000 units | API, CE, ISO |

| BoltMaster Industries | 21 days | 10,000 units | ASME, DNV |

| DeckSteel Pro | 10 days | 2,500 units | ASTM, Lloyd's |

Custom Engineering Specifications

Specialized stud bolt steel deck companies accommodate non-standard requirements through:

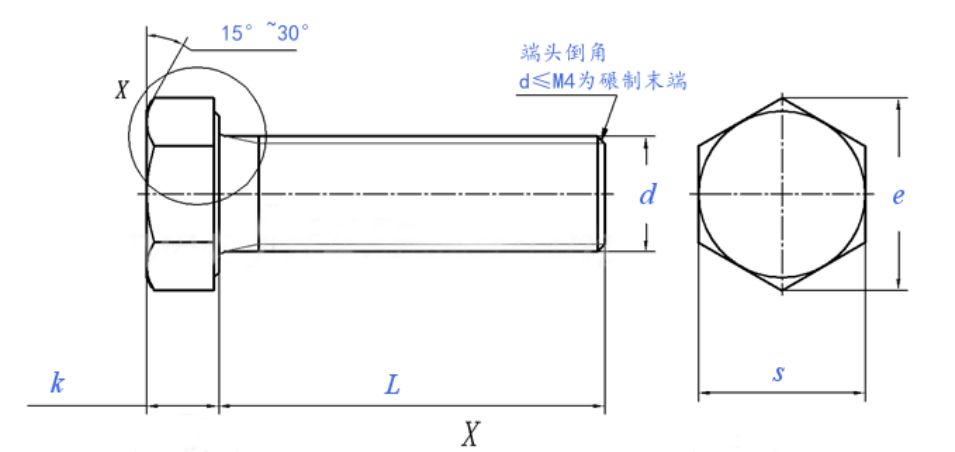

- Diameter customization: M12 to M64

- Alternative coatings (Xylan, Dacromet)

- Pre-assembled deck modules

Project Implementation Case Studies

A recent offshore wind farm installation utilized 28,000 galvanized stud bolts across 112 deck sections, reducing assembly time by 40% versus conventional welding methods. Key parameters included:

- Material: ASTM A193 B7

- Torque: 450 N·m ±5%

- Vibration resistance: 15-500 Hz

Advancing Structural Connection Systems

Innovations in stud bolt steel deck technology now incorporate smart tension monitoring via embedded sensors, providing real-time load data through IoT integration. This development aligns with global infrastructure digitization initiatives while maintaining backward compatibility with existing systems.

(stud bolt steel deck)

FAQS on stud bolt steel deck

Q: What factors should I consider when choosing stud bolt steel deck suppliers?

A: Prioritize suppliers with certifications (e.g., ISO), proven expertise in steel deck manufacturing, and a track record of timely delivery. Ensure they provide material test reports for compliance.

Q: How does a stud bolt steel deck factory ensure product quality?

A: Reputable factories use high-grade materials, advanced welding techniques, and rigorous quality checks. Many follow ASTM or EN standards to guarantee durability and load-bearing capacity.

Q: What services do stud bolt steel deck companies typically offer?

A: Companies often provide design consultation, custom fabrication, and on-site installation support. Some also offer corrosion-resistant coatings and project-specific engineering solutions.

Q: Can stud bolt steel deck suppliers accommodate custom specifications?

A: Leading suppliers can customize bolt diameters, deck thickness, and spacing patterns. They often work with CAD designs to meet unique architectural requirements.

Q: How do I verify the reliability of a stud bolt steel deck factory?

A: Check for industry certifications, client testimonials, and completed project portfolios. Physical factory audits and third-party inspection reports further validate production capabilities.

Latest news

-

Unlocking Industrial Strength: The Complete Guide to Better Bolts

NewsNov.24,2025

-

Durable & Versatile Square Head Bolts for Global Industry | YZ Fastener

NewsNov.23,2025

-

Huck Bolts – Strong, Reliable Industrial Fastening Solutions Explained

NewsNov.22,2025

-

Allen Head Bolts – Essential Fasteners for Global Industry & Innovation

NewsNov.22,2025

-

Elevator Bolts – Durable Conveyor & Industrial Fasteners | YZ Fastener

NewsNov.21,2025

-

Black Stud Bolts A193-B7/A194-2H-Handan Yanzhao Fasteners|High Strength&Corrosion Resistance

NewsNov.21,2025