drill bolts factories

Pro . 12, 2024 19:47 Back to list

drill bolts factories

The Landscape of Drill Bolt Factories An Overview

In the world of manufacturing, drill bolts play a crucial role in various industries, from construction to automotive to aerospace. The demand for high-quality drill bolts is ever-increasing, and consequently, drill bolt factories have become integral to the supply chain. This article explores the significance of drill bolt factories, the manufacturing process, and the modern challenges they face.

Importance of Drill Bolts

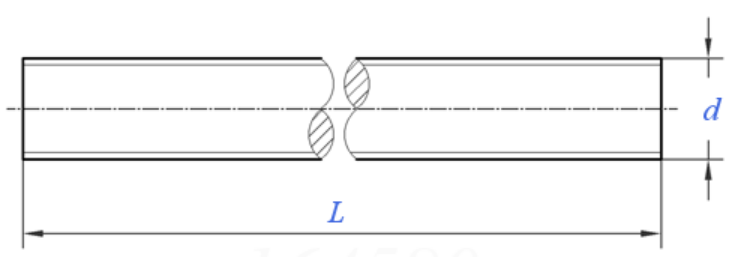

Drill bolts are specialized fastening devices often used to hold together components in machinery, vehicles, and structures. Their main function is to provide a strong, reliable connection while allowing for easy assembly and disassembly. They come in various sizes, materials, and designs to meet specific requirements. The strength and durability of drill bolts are vital for ensuring the safety and efficiency of the machinery or structure they are used in.

The versatility of drill bolts means they are found in numerous applications. In the construction industry, they are utilized for framing and structural integrity, while in automotive manufacturing, they are essential for assembling engines and chassis. The aerospace sector also relies heavily on drill bolts, where precision and reliability are of utmost importance.

The Manufacturing Process

The production of drill bolts involves several steps, each requiring precision and expertise. The process typically begins with the selection of raw materials, which may include various grades of steel, aluminum, or specialized alloys. These materials are chosen based on the required strength, weight, and resistance to corrosion.

Once the materials are selected, they undergo a process of cutting and shaping. This is often done through cold forging, a method that enhances the strength of the bolt by altering its grain structure. The bolts are then threaded, which allows for easier installation and ensures a secure fit.

After threading, the bolts undergo a series of treatments, such as heat treatment, to further increase their strength and durability. They may also be coated to provide additional corrosion resistance, a crucial factor in determining their longevity, especially in harsh environments.

Finally, the finished products undergo stringent quality control checks. This is a critical step, as the performance of drill bolts can directly impact the safety and effectiveness of the end product in which they are used.

drill bolts factories

Technological Advancements

In recent years, the drill bolt manufacturing industry has seen significant advancements due to technology. Automation has transformed the manufacturing process, increasing efficiency and reducing human error. Computer Numerical Control (CNC) machines are now commonly used for precision manufacturing, allowing factories to produce high volumes of drill bolts with intricate designs and specifications.

Moreover, advancements in materials science have led to the development of stronger and lighter materials. Factory operators are increasingly focusing on research and development to improve product performance and addressing the needs of specific sectors. The use of 3D printing technology is also on the rise, presenting opportunities for customization and quicker prototyping.

Challenges Faced by Drill Bolt Factories

Despite the progress and innovations, drill bolt factories face various challenges. One major issue is the fluctuation in raw material prices. As global markets experience volatility, the cost of materials like steel can significantly impact production costs, prompting factories to manage operational budgets diligently.

Another challenge is the increasing demand for sustainable practices. With growing environmental consciousness, drill bolt factories are under pressure to adopt greener manufacturing processes and reduce waste. This often requires investment in eco-friendly technologies, which can be financially challenging for smaller manufacturers.

Moreover, the competition within the industry is fierce. With the globalization of supply chains, factories not only compete locally but also on an international scale. This necessitates continuous improvement in product quality and customer service to stay ahead.

Conclusion

Drill bolt factories are a vital component of modern manufacturing, providing essential products that support a diverse range of industries. Through innovative manufacturing processes and technological advancements, these factories have enhanced their efficiency and product quality. However, they must navigate challenges such as fluctuating raw material costs and the shift towards sustainable practices. As industries continue to evolve, the role of drill bolt factories will remain critical in ensuring safety and reliability across various applications.

Latest news

-

Reliable Cabinet Bolts Supplier – Quality Fasteners for Cabinets

NewsJul.27,2025

-

Premium Phosphated Drywall Screws Supplier & Manufacturer Solutions

NewsJul.26,2025

-

Top Metric Wood Screw Companies – Reliable Manufacturer & Supplier

NewsJul.25,2025

-

Reliable Axle Nuts Supplier - Quality Manufacturing & Export Services

NewsJul.24,2025

-

Top Wire Bolts Suppliers & Exporters - Quality Fasteners Factory

NewsJul.23,2025

-

Reliable Wire Bolts Company & Supplier for Construction Solutions

NewsJul.22,2025