zinc plated stud bolt

Jan . 14, 2025 12:00 Back to list

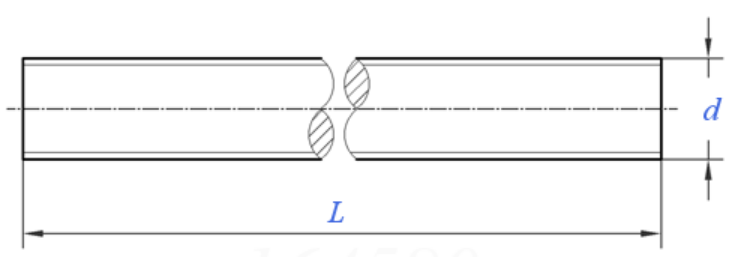

zinc plated stud bolt

Zinc plated stud bolts have become a vital component in various industries, offering an impeccable balance of durability, corrosion resistance, and cost-effectiveness. Recognized for their versatility, these fasteners are often employed in construction, automotive, and marine applications where reliability is paramount and the environmental conditions can be demanding.

In the realm of marine applications, zinc plated stud bolts excel in an environment notorious for corrosion challenges. The salty, moist atmosphere poses a continuous threat to metal components used in boat construction and repair. The added protection offered by zinc plating ensures that these bolts hold up under extreme conditions, ensuring both the safety and longevity of marine vessels. This is where the authority of zinc plated fasteners is most prominently displayed, withstanding a rigorous environment that tests all materials to their limits. The trustworthiness of zinc plated stud bolts also matters because of their environmentally friendly profile. The zinc plating process has evolved through technological advancements to minimize environmental impact, making it a preferred option for eco-conscious industries. This aligns with modern regulatory standards, ensuring compliance without compromising on performance. In conclusion, zinc plated stud bolts continue to rise in popularity due to their unmatched qualities of resilience and reliability across multiple sectors. Their role in enhancing structural integrity and operational efficiency underlines the expertise required in selecting the right materials for the job. As industries increasingly demand components that deliver on both performance and environmental sustainability, these bolts provide a trustworthy solution, backed by years of proven application and technological advancement. Embracing the use of zinc plated stud bolts is a testament to a commitment to quality and professionalism in technical fields.

In the realm of marine applications, zinc plated stud bolts excel in an environment notorious for corrosion challenges. The salty, moist atmosphere poses a continuous threat to metal components used in boat construction and repair. The added protection offered by zinc plating ensures that these bolts hold up under extreme conditions, ensuring both the safety and longevity of marine vessels. This is where the authority of zinc plated fasteners is most prominently displayed, withstanding a rigorous environment that tests all materials to their limits. The trustworthiness of zinc plated stud bolts also matters because of their environmentally friendly profile. The zinc plating process has evolved through technological advancements to minimize environmental impact, making it a preferred option for eco-conscious industries. This aligns with modern regulatory standards, ensuring compliance without compromising on performance. In conclusion, zinc plated stud bolts continue to rise in popularity due to their unmatched qualities of resilience and reliability across multiple sectors. Their role in enhancing structural integrity and operational efficiency underlines the expertise required in selecting the right materials for the job. As industries increasingly demand components that deliver on both performance and environmental sustainability, these bolts provide a trustworthy solution, backed by years of proven application and technological advancement. Embracing the use of zinc plated stud bolts is a testament to a commitment to quality and professionalism in technical fields.

Next:

Latest news

-

Premium Cabinet Bolts Supplier - Quality & Wholesale Fasteners

NewsAug.09,2025

-

Reliable Cabinet Bolts Supplier | Quality & Bulk Fasteners

NewsAug.07,2025

-

Wire Bolts Suppliers & Manufacturer | Factory Direct Price

NewsAug.06,2025

-

Premium Wire Bolts Suppliers | High-Quality Bolts

NewsAug.05,2025

-

Trusted Wire Bolts Suppliers - Durable & Reliable Solutions

NewsAug.04,2025

-

Wire Bolts Company | Premium Industrial Fasteners

NewsAug.03,2025