4l60e torque converter bolts

gen. . 30, 2025 01:58 Back to list

4l60e torque converter bolts

The 4L60E torque converter is a crucial component for those in the automotive repair and customization industry, specifically for individuals working with GM vehicles from the early 1990s to mid-2000s. Understanding the intricacies of torque converter bolt installation can greatly enhance the performance and reliability of your transmission systems, making this an essential skill for both seasoned mechanics and automotive enthusiasts. This article delves into the key aspects associated with 4L60E torque converter bolts, offering insight into best practices, expert tips, and a deep dive into their role in ensuring optimal vehicle performance.

Furthermore, employing locking compounds such as Loctite can provide additional security by preventing the bolts from loosening due to vibrations and thermal expansion. However, it's essential to ensure the threads are clean and free from oil or debris to maximize the efficacy of these compounds. Another significant topic of discussion among automotive experts is the importance of regularly inspecting these bolts. Given the rigorous conditions under which many vehicles operate, periodic checks can preemptively address potential issues. Look for signs of wear or deformation, as these can indicate existing or impending problems. Quick identification and correction of faults can prevent further damage to the transmission, saving both time and costs associated with extensive repairs. Safety should never be overlooked. Ensure the vehicle is adequately supported on jack stands before beginning any repair work. Incorrect handling of automotive components can lead to disastrous outcomes, not to mention void warranties or cause personal harm. In summary, the 4L60E torque converter bolts might seem like minor components, but their role is crucial in the grand scheme of a vehicle’s performance and reliability. Investing in high-quality bolts and adhering to proper installation practices can significantly enhance transmission life and vehicle reliability. For those involved in performance tuning or heavy-duty applications, selecting components from reputable manufacturers and conducting regular maintenance checks are steps in the right direction. Through these measures, the harmony between the engine and transmission can be ensured, translating to smoother rides and peace of mind for vehicle operators. As advancements in automotive technology progress, staying informed and adapting to new methodologies related to torque converter bolt use will be both a challenge and a path to mastery for dedicated professionals in this field.

Furthermore, employing locking compounds such as Loctite can provide additional security by preventing the bolts from loosening due to vibrations and thermal expansion. However, it's essential to ensure the threads are clean and free from oil or debris to maximize the efficacy of these compounds. Another significant topic of discussion among automotive experts is the importance of regularly inspecting these bolts. Given the rigorous conditions under which many vehicles operate, periodic checks can preemptively address potential issues. Look for signs of wear or deformation, as these can indicate existing or impending problems. Quick identification and correction of faults can prevent further damage to the transmission, saving both time and costs associated with extensive repairs. Safety should never be overlooked. Ensure the vehicle is adequately supported on jack stands before beginning any repair work. Incorrect handling of automotive components can lead to disastrous outcomes, not to mention void warranties or cause personal harm. In summary, the 4L60E torque converter bolts might seem like minor components, but their role is crucial in the grand scheme of a vehicle’s performance and reliability. Investing in high-quality bolts and adhering to proper installation practices can significantly enhance transmission life and vehicle reliability. For those involved in performance tuning or heavy-duty applications, selecting components from reputable manufacturers and conducting regular maintenance checks are steps in the right direction. Through these measures, the harmony between the engine and transmission can be ensured, translating to smoother rides and peace of mind for vehicle operators. As advancements in automotive technology progress, staying informed and adapting to new methodologies related to torque converter bolt use will be both a challenge and a path to mastery for dedicated professionals in this field.

Next:

Latest news

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

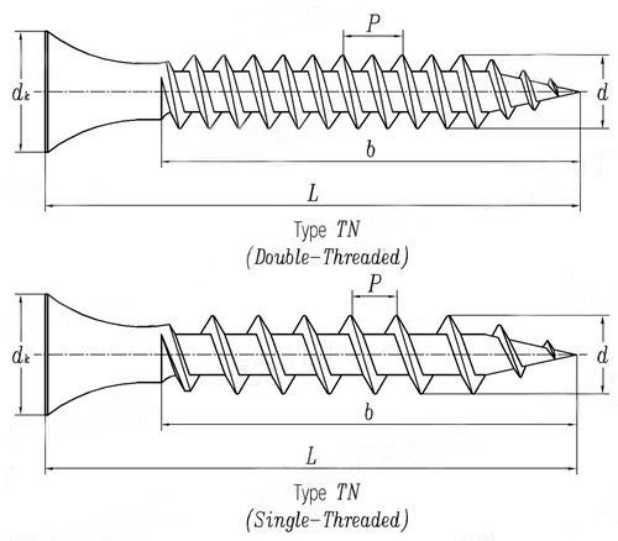

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025