gb flange nuts

ян. . 16, 2025 05:44 Back to list

gb flange nuts

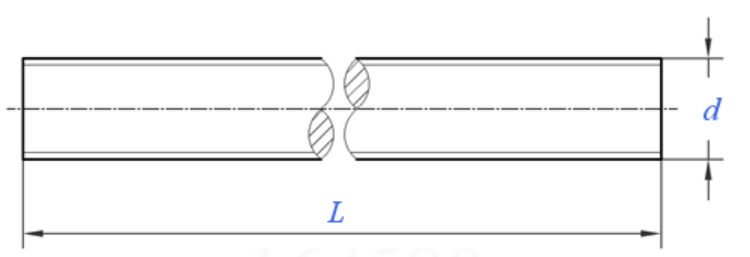

GB flange nuts, an essential component in numerous industrial applications, stand out as a pinnacle of engineering by blending practicality with durability. Flange nuts, characterized by their wide base or flange on one end which serves as an integrated washer, offer significant advantages in distributing the nut's pressure over the part being secured, significantly reducing the risk of damage.

Trustworthiness in GB flange nuts is fortified through a track record of reliability and performance. Repeatedly subjected to stringent quality assurance tests, these components provide peace of mind that once installed, they require minimal intervention. This assurance empowers engineers to trust in their builds, knowing that their choice of fastening solutions will not compromise performance or safety. The quality control processes involve testing nut hardness, threading precision, and corrosion resistance, making these components highly reliable in diverse applications. Incorporating GB flange nuts into your projects translates to a commitment to quality and assurance. The meticulous crafting process, aligned with both hands-on expertise and innovative manufacturing technologies, provides flange nuts that serve as a linchpin for a vast range of applications. Whether involved in new assemblies or the retrofitting of existing equipment, the use of these nuts delivers increased efficiency and reduced downtime. Exploring further into their application, GB flange nuts facilitate an ease of use that tradespeople value highly. Their design simplifies the installation process, reducing the number of components required and, consequently, the time spent on assembling. This efficiency is not just a convenience but a strategic advantage in industries where time and reliability are critical. In conclusion, GB flange nuts are not merely a component; they are a culmination of technology, material science, and real-world demands. Their integration into industries worldwide speaks volumes of their superiority in fastening solutions. When choosing nuts that promise and deliver under pressure, GB flange nuts are the authoritative choice, ensuring every project achieves its maximum potential in safety and functionality.

Trustworthiness in GB flange nuts is fortified through a track record of reliability and performance. Repeatedly subjected to stringent quality assurance tests, these components provide peace of mind that once installed, they require minimal intervention. This assurance empowers engineers to trust in their builds, knowing that their choice of fastening solutions will not compromise performance or safety. The quality control processes involve testing nut hardness, threading precision, and corrosion resistance, making these components highly reliable in diverse applications. Incorporating GB flange nuts into your projects translates to a commitment to quality and assurance. The meticulous crafting process, aligned with both hands-on expertise and innovative manufacturing technologies, provides flange nuts that serve as a linchpin for a vast range of applications. Whether involved in new assemblies or the retrofitting of existing equipment, the use of these nuts delivers increased efficiency and reduced downtime. Exploring further into their application, GB flange nuts facilitate an ease of use that tradespeople value highly. Their design simplifies the installation process, reducing the number of components required and, consequently, the time spent on assembling. This efficiency is not just a convenience but a strategic advantage in industries where time and reliability are critical. In conclusion, GB flange nuts are not merely a component; they are a culmination of technology, material science, and real-world demands. Their integration into industries worldwide speaks volumes of their superiority in fastening solutions. When choosing nuts that promise and deliver under pressure, GB flange nuts are the authoritative choice, ensuring every project achieves its maximum potential in safety and functionality.

Next:

Latest news

-

Reliable Wire Bolts Company & Supplier for Construction Solutions

NewsJul.22,2025

-

Premium Spike Wheel Nuts Supplier | Durable Quality

NewsJul.21,2025

-

High Strength Black & Galvanized Hex Bolts DIN933/931 GB5782/5783

NewsJul.20,2025

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025