grade8.8 thread rods factory

Каст . 12, 2024 14:51 Back to list

grade8.8 thread rods factory

The Production and Significance of Grade 8.8 Thread Rods A Comprehensive Overview

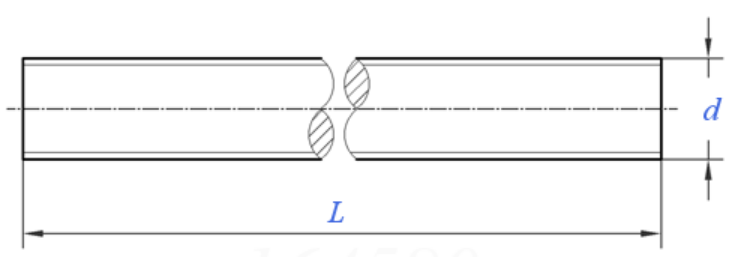

Thread rods, commonly known as threaded rods or studs, are essential components in various industrial and construction applications. Among the many grades available, Grade 8.8 thread rods are particularly notable due to their high strength and durability, making them a preferred choice in demanding environments.

Grade 8.8 thread rods are made from medium carbon steel and undergo a quenching and tempering heat treatment process. This method enhances their mechanical properties, resulting in a tensile strength of 800 MPa and a minimum yield strength of 640 MPa. The numerical designation 8.8 signifies the material's tensile strength in megapascals (MPa), coupled with a yield strength that is 80% of the tensile strength. This combination makes Grade 8.8 thread rods exceptionally effective in applications where high load-bearing capacity and resistance to deformation are crucial.

In a manufacturing factory specializing in Grade 8.8 thread rods, the production process typically consists of several stages, including raw material selection, forging, machining, and surface treatment. Quality control is integral throughout these stages to ensure that each thread rod meets the stringent standards required for various applications. The raw material, usually sourced from reputable suppliers, undergoes inspections to guarantee its composition and properties.

grade8.8 thread rods factory

Once the quality of the raw material is confirmed, the forging process begins. This involves shaping the metal through controlled deformation, which not only creates the preliminary form of the rod but also enhances its grain structure and overall strength. After forging, the rods are cut to the desired lengths and machined to precise specifications. This machining phase includes threading, where the external surface of the rod is enhanced with consistent, uniform threads that facilitate easy fastening.

Surface treatment is another crucial step that cannot be overlooked. It serves to improve the corrosion resistance of the rods, thereby extending their lifespan, especially in harsh environments. Common surface treatments include galvanization, which provides a protective zinc coating, and passivation, which forms a protective oxide layer.

Grade 8.8 thread rods find extensive use in a myriad of sectors, including construction, automotive, aerospace, and manufacturing. Their robustness makes them ideal for applications such as bridges, machinery assembly, and structural reinforcements, where safety and reliability are paramount.

In conclusion, the manufacture of Grade 8.8 thread rods represents a critical aspect of modern industry. With their superior strength and reliability, these components play an indispensable role in ensuring the integrity and durability of countless structures and machines. As industries continue to evolve, the demand for high-quality fasteners like Grade 8.8 thread rods will undoubtedly remain strong, underscoring the importance of specialized factories dedicated to their production.

Latest news

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025