High-Quality Galvanized Screws Manufacturer | Durable & Corrosion-Resistant Fasteners

Верас . 06, 2024 02:30 Back to list

High-Quality Galvanized Screws Manufacturer | Durable & Corrosion-Resistant Fasteners

The Importance of Galvanized Screws in Construction and Manufacturing

Galvanized screws are an essential component in both construction and manufacturing industries, owing to their unique properties and advantages over standard screws. The process of galvanization involves coating steel screws with a layer of zinc, which significantly enhances their resistance to corrosion. This quality makes galvanized screws an ideal choice for outdoor applications where exposure to moisture and the elements can lead to rust and degradation of materials.

One of the primary benefits of using galvanized screws is their durability. The zinc coating not only protects the steel from rust but also improves its overall strength. This makes galvanized screws particularly suitable for heavy-duty applications, including structural assemblies, roofing, and decking. As a result, manufacturers of galvanized screws often cater to diverse sectors, such as construction, automotive, and appliance manufacturing, providing reliable fastening solutions that ensure the longevity and safety of the assembled products.

In construction, galvanized screws are widely used in wood framing, decking, and siding installations. Their corrosion resistance is crucial when fasteners are used in treated lumber, which is often laden with chemicals that can accelerate the rusting of standard screws. Choosing galvanized screws prevents costly repairs and replacements, thereby saving time and money for builders and contractors.

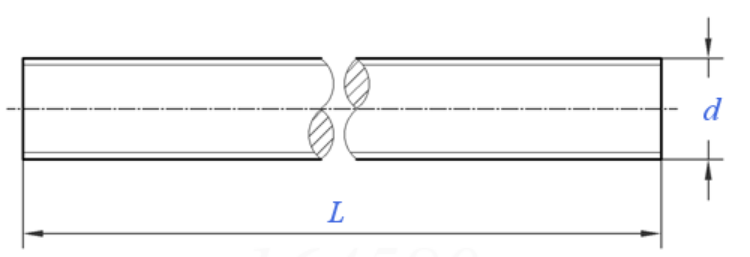

galvanized screws manufacturer

Moreover, galvanized screws are available in various sizes and types, including wood screws, machine screws, and self-tapping screws, making them versatile for many applications. Manufacturers of these screws often offer customized solutions to meet specific project requirements, allowing engineers and architects to source fasteners that align perfectly with their design specifications.

When selecting a galvanized screws manufacturer, it is important to consider factors such as product quality, manufacturing standards, and compliance with industry regulations

. Reputable manufacturers invest in advanced manufacturing techniques and quality control processes to ensure their screws meet strict performance criteria. This commitment to quality not only enhances the reliability of their products but also builds trust with customers who depend on these fasteners for critical applications.In summary, galvanized screws play a vital role in ensuring the durability and integrity of various structures and products. The corrosion-resistant properties afforded by the galvanization process make them indispensable in outdoor and high-moisture environments. As the demand for building materials and manufacturing components continues to grow, the importance of partnering with a reliable galvanized screws manufacturer cannot be overstated. These manufacturers not only provide the necessary products but also contribute to the overall success and safety of various projects in diverse industries.

Latest news

-

Premium Wood Screws for Flooring - Reliable Wood Floor Screws Company & Suppliers

NewsJun.24,2025

-

High-Quality Cabinet Bolts – Reliable Factory, Trusted Company & Leading Suppliers

NewsJun.10,2025

-

Dragon Bolts UNF Wholesale – Top OSRS Dragon Bolts UNF Manufacturer & Exporter

NewsJun.10,2025

-

Premium Wind Lock Washers - Secure Anti-Vibration Solution

NewsJun.10,2025

-

Stainless Steel Socket Head Cap Screws High Strength & Corrosion-Resistant

NewsJun.10,2025

-

Shake Proof Washers Durable Anti-Vibration Locking Solutions

NewsJun.09,2025